Featured Projects

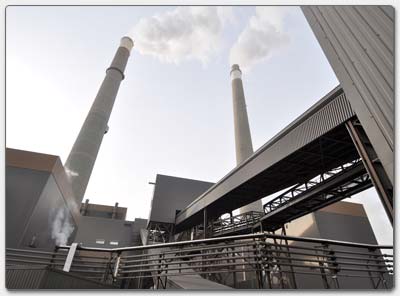

Xcel Energy's Comanche Station

Construction on Xcel Energy’s first new coal-fired electric generation unit in approximately 30 years was completed on schedule for its 2010 service date. Comanche Station near Pueblo, Colorado, is the site of the 750-megawatt generating unit that will use a highly efficient supercritical boiler and will have state-of-the art emission controls. FPD also provided all the electrical construction services for the new coal handling system, along with the emissions upgrades on units 1 & 2.

When FPD first mobilized to Xcel Energy’s Comanche Station in Pueblo, Colorado, we had no idea that Xcel would be so happy with our work that our scope would be increased enough to keep us onsite for over four years. FPD’s first major project at the site was the emissions reduction work on Units 1 & 2. This complex work inside the existing 35-year-old plant was completed within tight deadlines imposed by the need for a plant outage, and FPD contributed extensive value engineering and constructability analysis for the design engineer.

FPD was then awarded a contract for all the electrical work on the Unit 3 Coal Handling system, and during this time was awarded a dozen or so other contracts for electrical work on hopper heaters, the clarifier, acid building, fire alarm systems, and heat tracing.

Although the entire Unit 3 construction was originally intended to be an EPC contract, Xcel was so impressed with the progress and efficiency shown by FPD on the Units 1 & 2 projects that the electrical portion of Unit 3 was awarded to FPD.

By the time all of FPD left site, the total project scope had grown to include almost 500,000 man-hours, 300,000 feet of conduit and 1.5 million feet of cable. Comanche Station is now the largest power generation facility in Colorado, producing 1,426 megawatts of electricity.

Great River Energy's Coal Creek Station

FPD was awarded the electrical construction contracts for Great River Energy’s Coal Creek Station Commercial Coal Drying project. This unique technology takes the lower-grade lignite coal available in North Dakota and removes moisture from it prior to combustion in the boiler, thereby increasing the efficiency of the boiler and providing environmental benefits. Owing to the unique technology being installed, FPD worked closely with engineers on the project to identify opportunities for value engineering and prevent constructability issues.

As FPD became involved in the project, it quickly became clear that the project schedule was extremely tight for the magnitude of work that was required. FPD mobilized in February 2009, and was able to support commercial operation by the end of 2009 by working two shifts, up to seven days a week at 12 hours per day, with peak manpower of nearly 230 electricians. In the 11 month duration of the project, FPD worked 262,000 man-hours, installed over 200,000 feet of conduit and over 1.1 million feet of cable. What made the project a true success was the collaboration and cooperation among all the parties involved with the project – from GRE’s own team to the engineers and all the contractors – who shared a common goal of completing the project within the strict regulatory deadline.

Black Hills Corporation's Pueblo Airport Generating Station

Through an extensive process of due diligence, Black Hills Corporation explored every possible contract arrangement for the work on its Pueblo Airport Generation Station project. Ultimately they awarded all the electrical work to FPD on a fixed price contract with firm schedule deadlines backed by Liquidated Damages provisions. This project, on a greenfield site northwest of the airport in Pueblo, Colorado, included a pair of GE LMS100 combustion turbines in simple cycle configuration, along with two steam turbines, each paired with two LM6000 combustion turbines in combined cycle configuration.

Due to some permitting delays, the schedule on the project was greatly compressed, with the bulk of FPD’s work taking place over an 8 month period. During this time, FPD electricians worked approximately 200,000 man-hours, installed 150,000 feet of above-ground conduit and 1.6 million feet of cable.